Injection molding of plastics

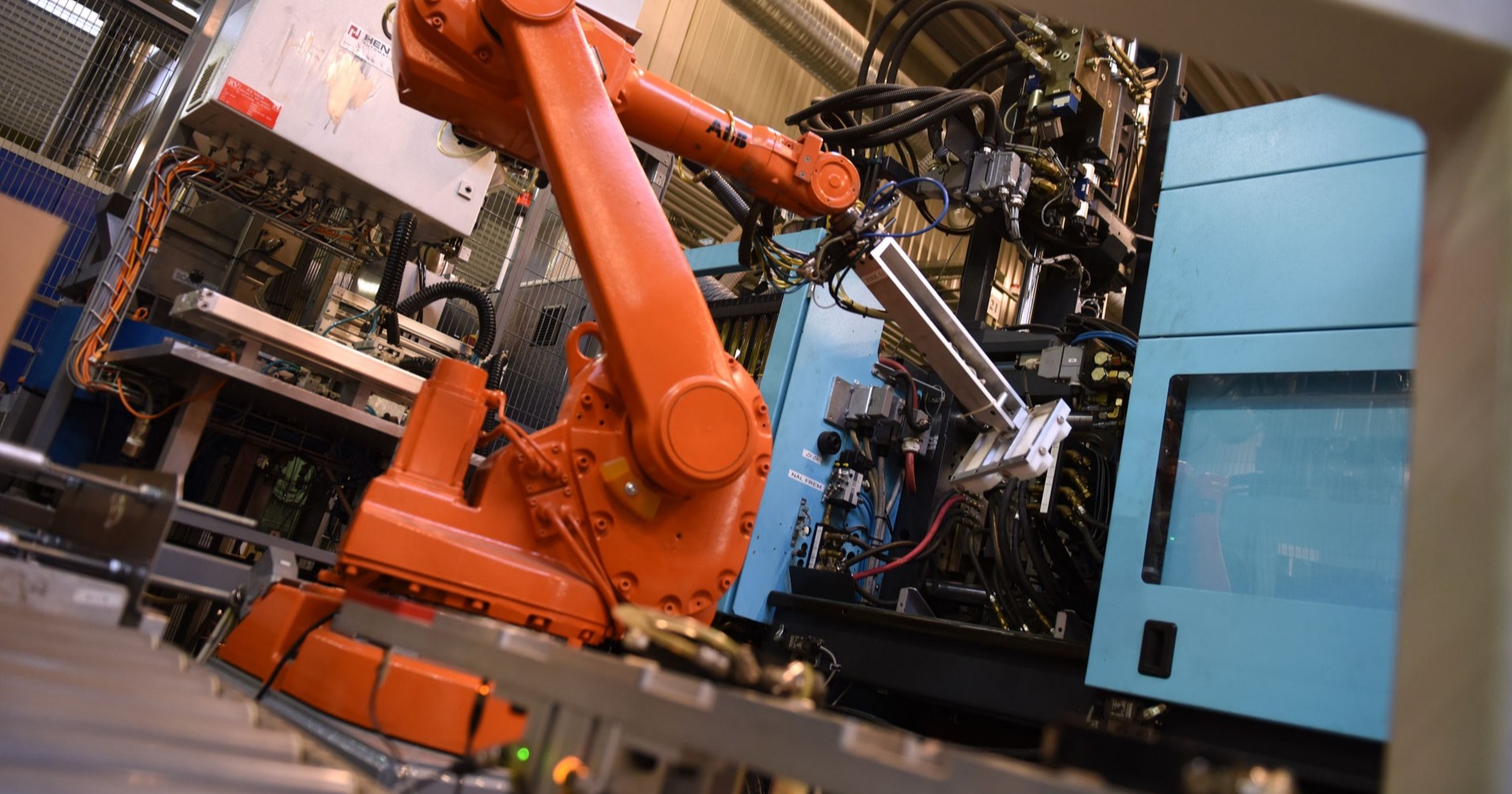

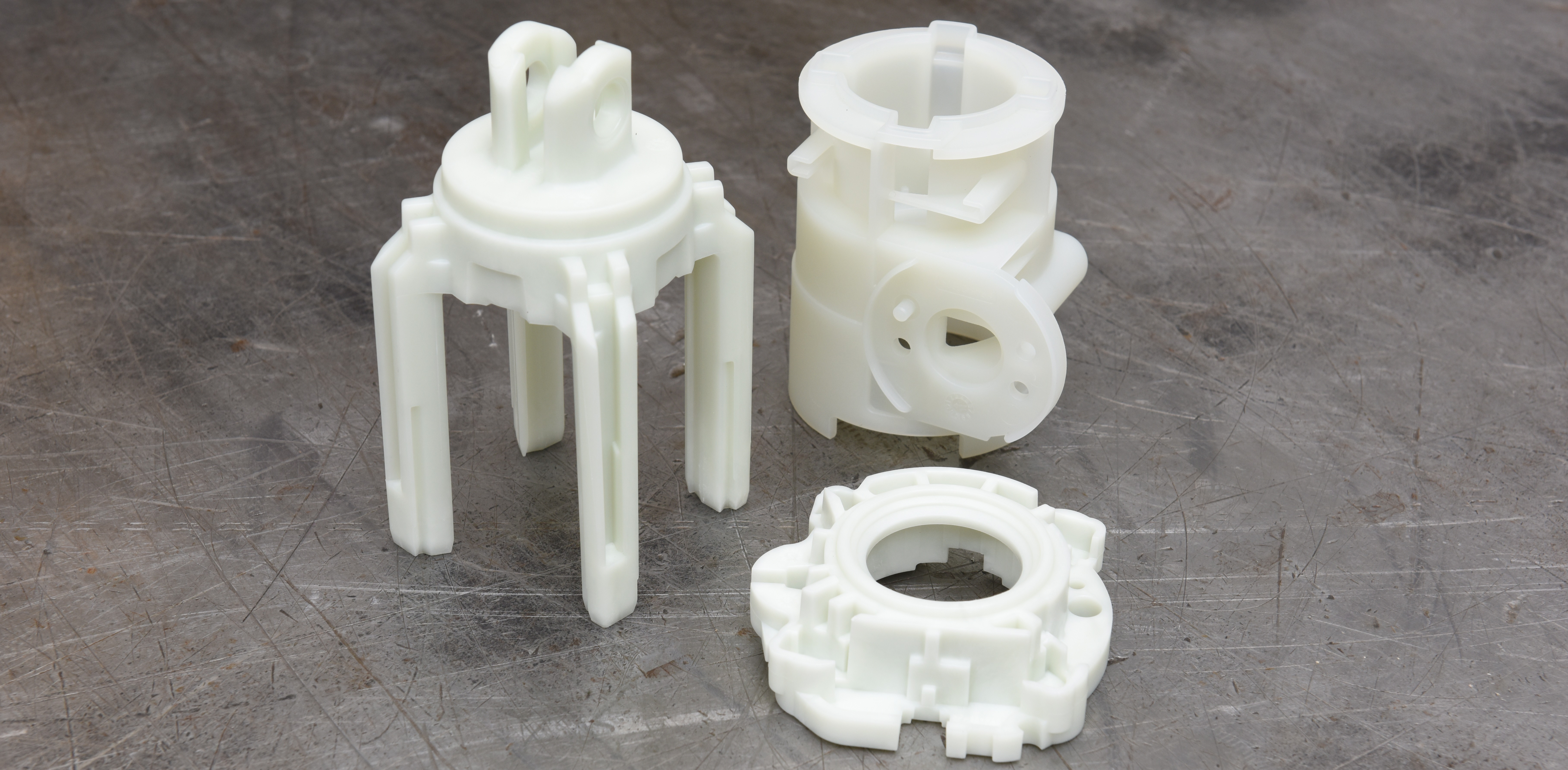

At Bogense Plast A/S, we injection mold technical plastic workpieces, i.e. workpieces with strict quality and dimension requirements, of advanced materials.

Injection molding of plastic is a periodic process, during which a given mass of raw plastic materials is plasticized, homogenized, and molten by heating and mechanical processing.

The molten mass is injected into a tool, which is clamped in an injection molding machine.

The tool, which is referred to as a molding or injection molding tool, has one or more cavities, i.e. mold cavities with the same geometry as the workpiece or workpieces to be produced.

The tool is tempered to a temperature lower than the dimensional stability temperature of the material. This causes the melt injected into the tool to solidify with the contour formed by the cavity.

The solidification begins during the injection from the walls of the cavity and continues towards the centre of the workpiece. The injected mass is kept under pressure until the gate has solidified, to prevent a backflow of the melt. At the same time, the pressure must ensure that the cavity is refilled to compensate for the volume loss that occurs during the cooling of the melt. The workpiece is cooled until it is so dimensionally stable that it can be removed from the tool manually or automatically.

-no2tl3.jpg)

The production time will determine the quality of the workpiece and depends on the material and on the wall thickness of the workpiece. It can take from less than one second and up to several minutes.

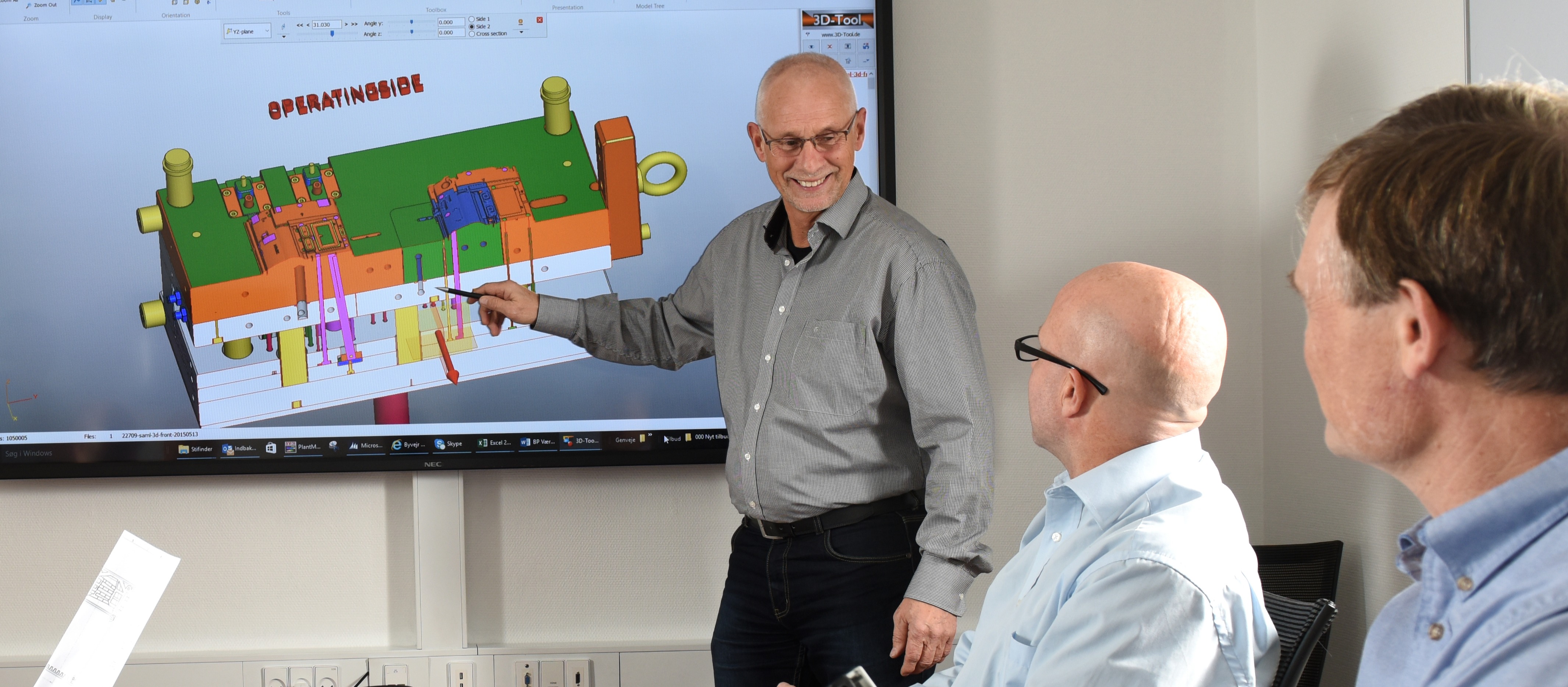

It may seem simple to produce workpieces using injection molding, but it often takes many hours, from when the workpiece is on the drawing board until an actual production.

At Bogense Plast A/S, we injection mold technical plastic workpieces, i.e. workpieces with strict quality and dimension requirements, of advanced materials.

The process starts in our Technical Department where, in collaboration with the customer and the selected toolmaker, the project manager constructs an injection molding tool to produce the workpiece designed by the customer. For a detailed description, please refer to The Process and Tool Manufacturing. The tool is then run in on the injection molding machine in the Production Department by specially trained operators before the product is released for production. For a detailed description of our production, please visit our website at Plastic Production.