Plastic production

The machines are operated by our experienced and qualified employees, who continuously improve and upgrade their skills, so that we can guarantee a high level of professionalism and constant optimization and improvement of operations.

The 3,500 m2 production area in modern facilities, which was established and taken into use in 2002, is the core of our company.

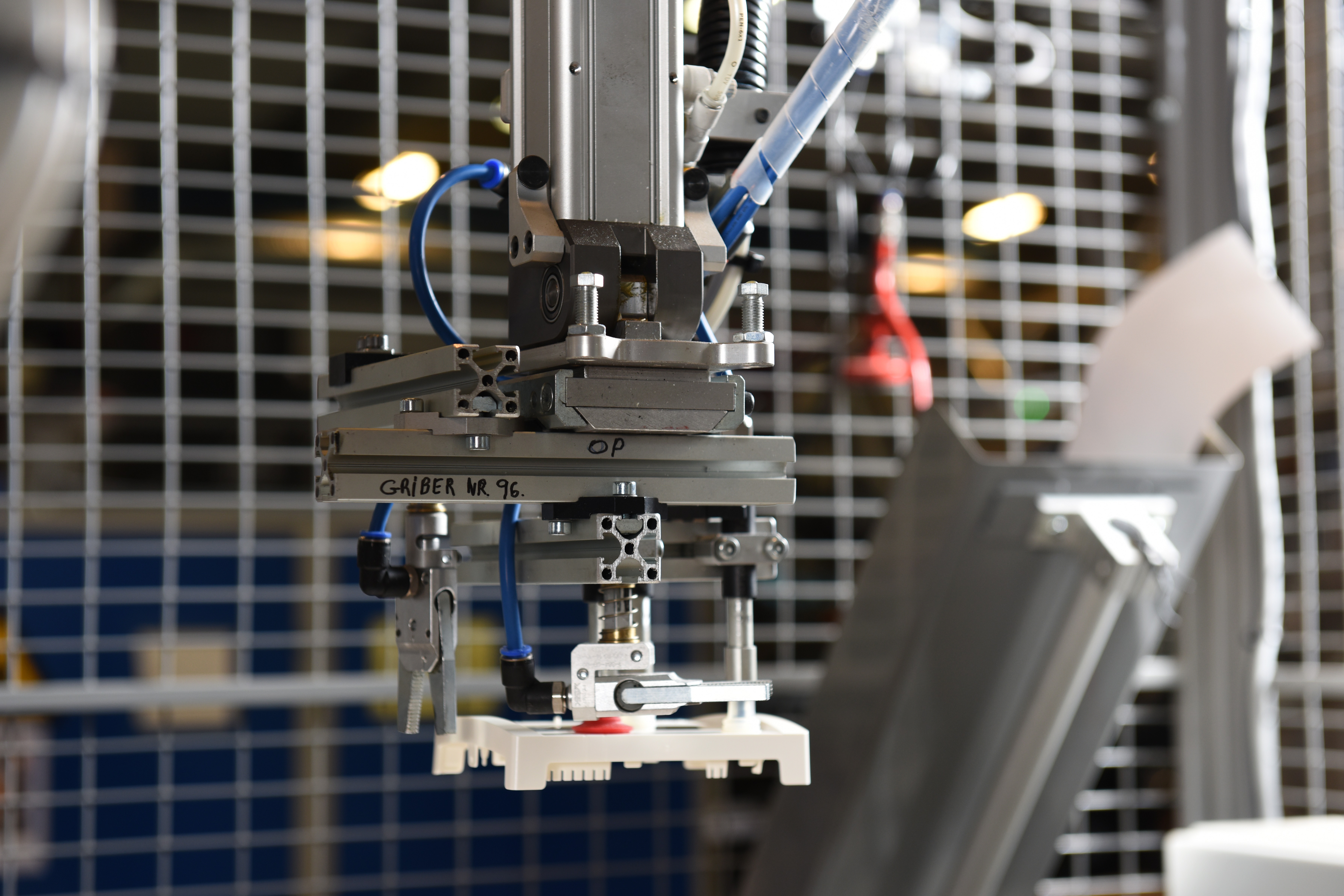

The production area currently houses 50 microprocessor-controlled DEMAG machines. DEMAG is characterized by the latest proven technology, high precision, and operational reliability.

The material is supplied through pipes from the central drying and transportation system to reduce manual lifting and transportation.

The machines are equipped with advanced robots and packaging machines that ensure automatic removal and further processing. This means that we can perform extraction, post-processing, and packaging without manual labour.

The machines are operated by our experienced and qualified employees, who continuously improve and upgrade their skills, so that we can guarantee a high level of professionalism and constant optimization and improvement of operations.

Our plastic production is planned and managed by the BARCO MES SYSTEM. The planning takes place on a visual planning board, which automatically exchanges data with our MP System and is online with terminals on all our injection molding machines through wireless communication. The terminals automatically record the machines' production and stop time as well as causes. Together, this ensures that we are continuously updated on the planning, production, and operational performance.