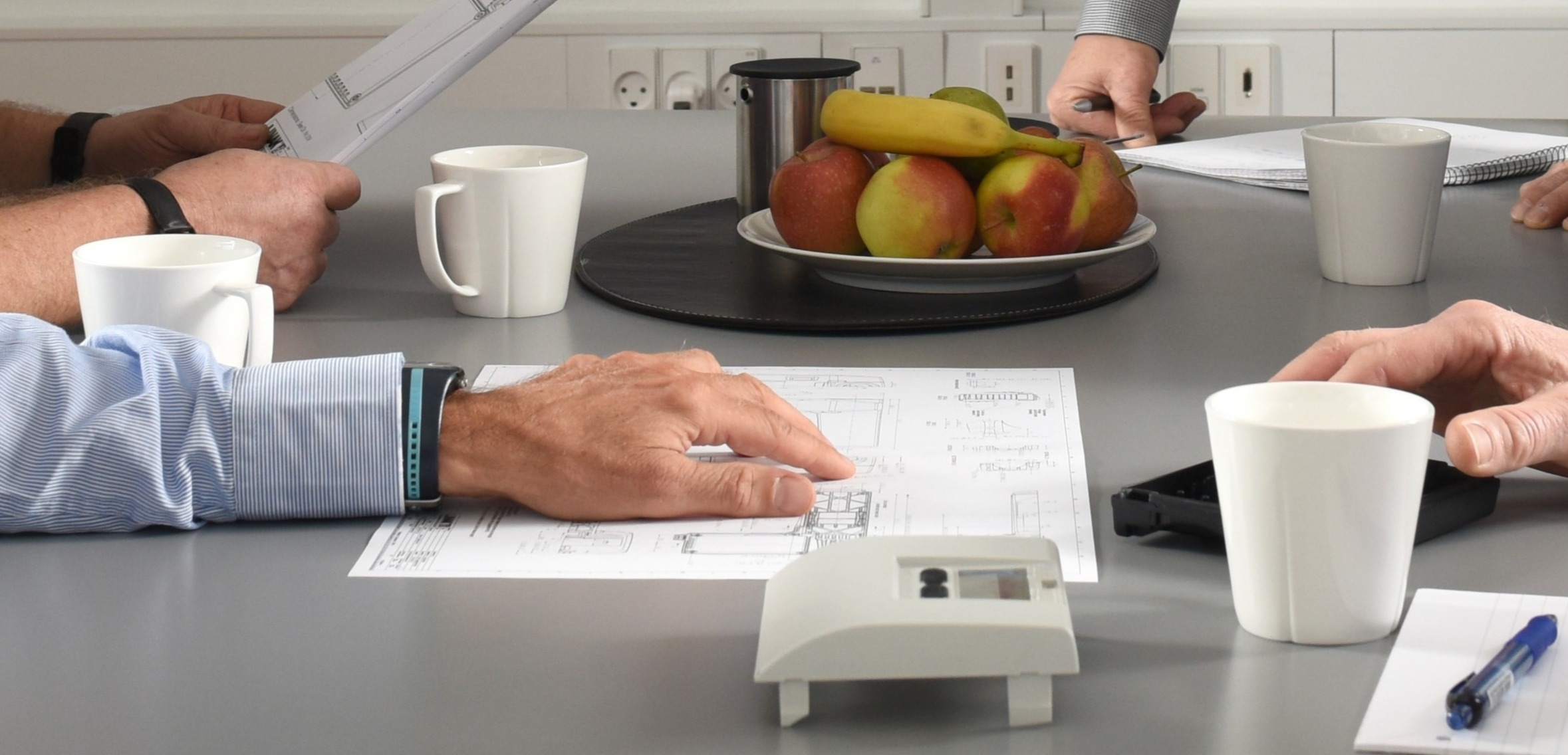

Product development

The ability to combine innovative thinking with precise knowledge is essential in your Development phase. Our engineers are updated on the latest materials and techniques, to help ensure that your product gets the best start.

You have an idea – together we will find the solution. Our plastic engineers have many years of experience in seeing the potential in each workpiece and the knowledge needed to help complete the development process. First, all the necessary mechanical, physical and thermal requirements for the workpiece are mapped. Once all the details have been described, the construction begins to take shape. During this phase, the ability to combine creative thinking with exact knowledge is crucial.

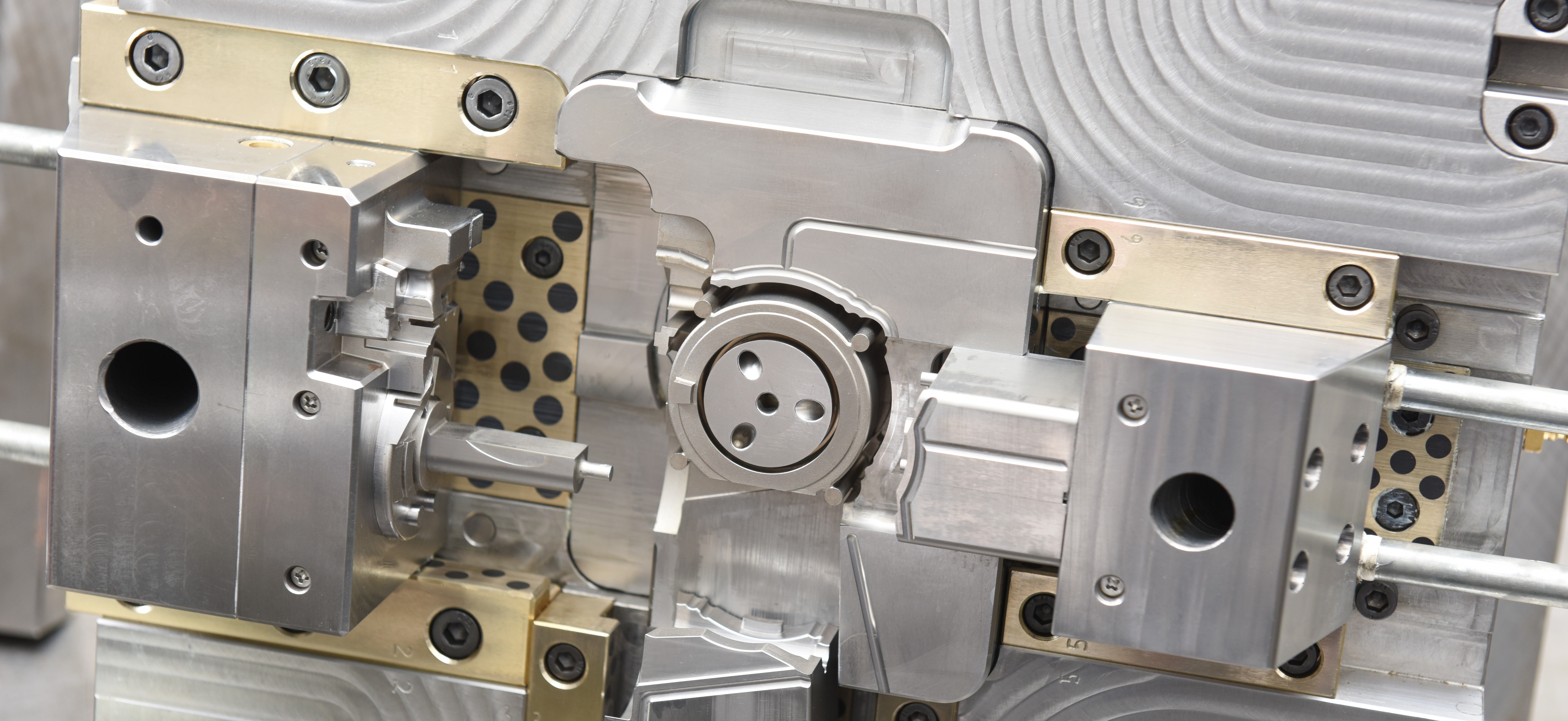

All doubts and potential errors must be identified during the start-up phase. To ensure this, we use several advanced computer tools. First, the workpiece is drawn in a 3D CAD program – possibly based on existing drawings transmitted by email. Next, we simulate the injection molding process using Mold-Flow. This technique is suitable for revealing weaknesses in the construction and thus paving the way for optimization of the result. Where necessary, an SLA model is produced for testing. After adjustment and customization, the thoroughly tested workpiece can now be "released" to the toolmaker.