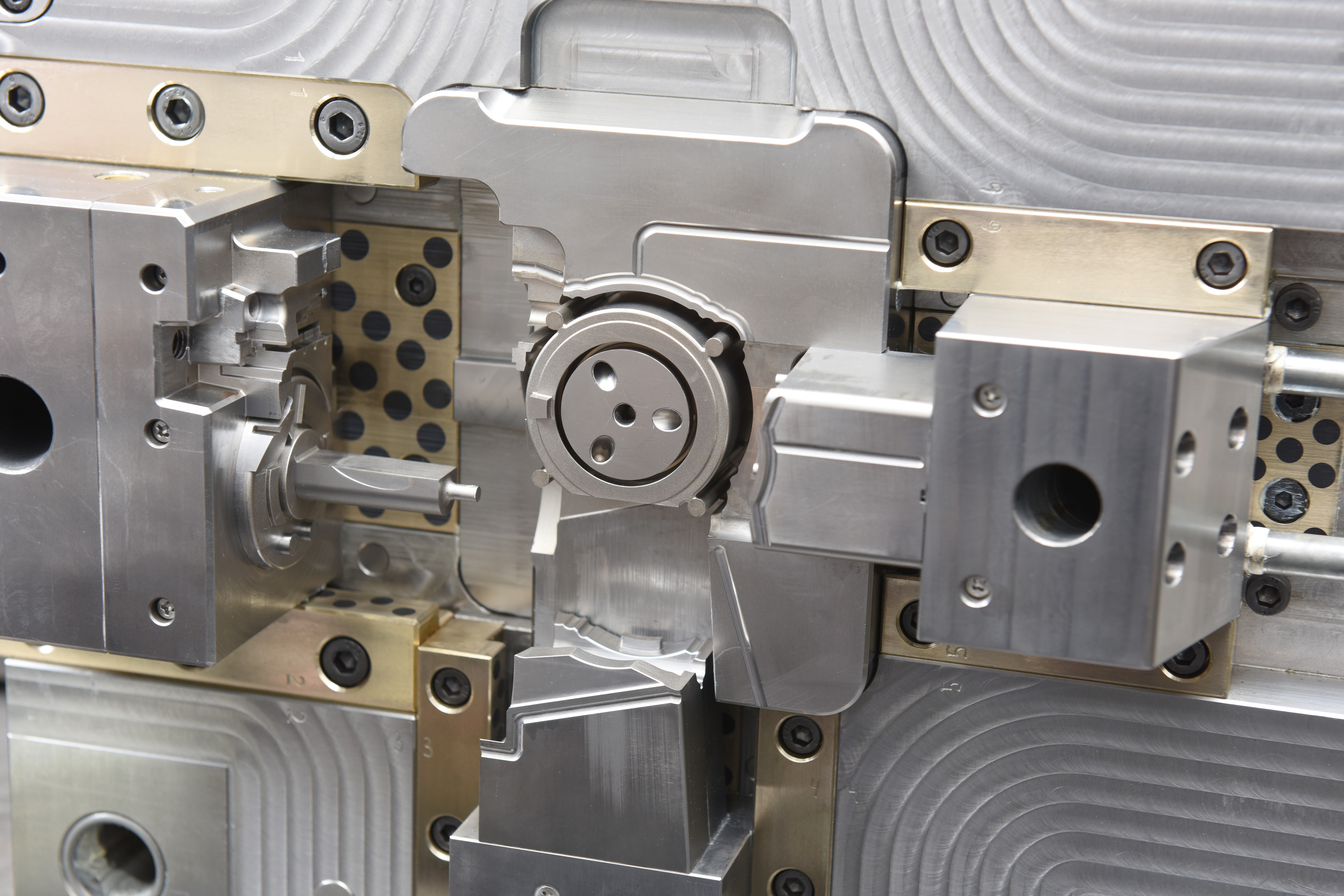

Tool manufacturing

Bogense Plast can draw on a large network of tool manufacturers, both domestically and abroad. Each task that determines who we use – this makes our prices competitive and our delivery time shorter.

Bogense Plast has always used external tool suppliers. This decision was made to ensure first-class quality regardless of the nature of the task.

It is our experience that an optimum solution requires specialized competences and equipment. And covering all areas with internal manpower and machinery is not profitable. Bogense Plast therefore draws on a large network of tool suppliers, both domestically and abroad. The special nature of each task determines who we use. As a result, we get better tools for the same price, and even in less time.

The choice of tool supplier is made as early in the process as possible. We draw on specialized expertise throughout the development process. The tool supplier is a natural part of the project group and contributes to the assessment and development of the workpiece throughout the phases. If production and delivery are to take place particularly quickly, we can put several tool suppliers on the same task. They are each assigned the part that best suits their expertise.

That way, we are often able to reduce the production maturity time by half or more.

Over the years, Bogense Plast has built a close collaboration with some of the best tool suppliers. We know their individual strengths – both in terms of craftsmanship and equipment. When we need to complete a task, we never doubt who is the best qualified to manufacture the tool.